When rolling mill rolls are supported by four-row cylindrical roller bearings, their structure is primarily based on the JB/T5389.1 (1995) standard. However, long-term use has revealed that the cage is prone to deformation during assembly, leading to premature bearing failure. Therefore, using the FC5274220 bearing produced by our company as an example, we have made the following structural improvements.

1. Disadvantages of the Original Bearing Structure

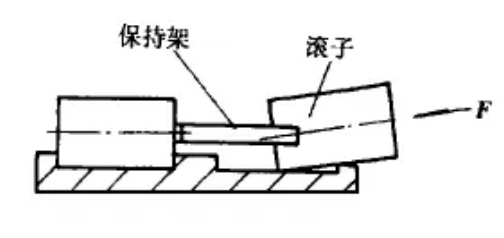

The original bearing used a brass comb-shaped cage with a notch machined into one side of the outer ring to accommodate the rollers. During assembly, a row of rollers must be installed into the cage through the notch. To ensure that the rollers do not fall out of the notch during normal operation, a minimum height requirement must be established relative to the raceway. Therefore, when installing the rollers, they must be tilted at a certain angle and then driven in firmly, rather than directly inserted, as shown in Figure 1. This causes the cage's lintels and pockets to deform, tilting toward the center of the bearing. The consequences are:

(1) The roller head droops, causing the inner circle size of the bearing to change, increasing the difficulty of on-site installation of the bearing. When using a robot for automatic assembly, the drooping roller head is easy to scratch the inner ring raceway, reducing the service life of the bearing.

(2) The gap between the roller and the cage pocket is uneven, so the cage cannot accurately guide the roller, the roller skew is aggravated, the bearing wear is accelerated, the operation is deteriorated, and the damage to the cage leads to the failure of the entire bearing. This is one of the main forms of damage to the rolling mill bearing.

(3) Since the roller hardness is higher than that of the outer ring, the outer ring raceway is easily scratched when the roller is installed, which poses a hidden danger to the normal operation of the bearing.

2 Features after structural improvement

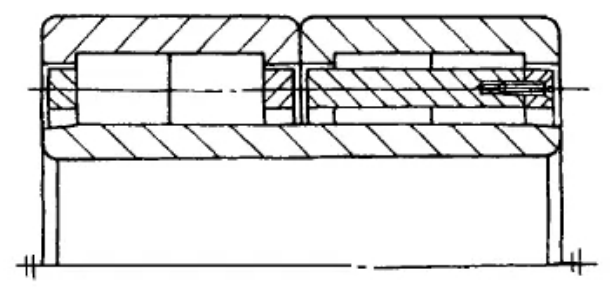

In view of the shortcomings of the original bearing structure, after repeated research and demonstration, a single-pocket brass solid cage was used to replace the original comb cage. The outer ring has no center edge and filling gap, and two rows of rollers are arranged side by side. To increase the strength of the cage and improve process performance, in addition to reducing one pocket, a new process using screws for fastening and industrial adhesives to prevent loosening was adopted to replace the rivet riveting process used in the original solid cage, as shown in Figure 2. This not only solves the problem of difficult rivet hole processing caused by the excessive length of the cage beam, but also fully guarantees the rigidity of the cage. Its advantages are:

(1) The cage deformation problem caused by rigid roller assembly is eliminated structurally, and the improvement of cage machining geometric accuracy and the overall performance of the bearing are organically combined. The bearing's operating defects such as roller head sagging, skewness, and raceway scratches caused by assembly are completely avoided structurally, and the bearing's operating reliability is greatly enhanced.

(2) After the outer ring center rib is eliminated, the effective length of the roller is increased, and the basic rated dynamic load of the bearing is increased from 1700kN to 1900kN. Under the same load, that is, the equivalent dynamic load remains unchanged, the basic rated life of the improved bearing is increased by 45% compared to the original load.

"To make the best quality in most competitive price",is our principle and "To support our clients enlarge their local market in max" is our continuous target